- The functions necessary to control various roll-to-roll devices such as paper/film processing, printing, and metal processing are organized into blocks. Packaged software allows for flexible adaptation to various device configurations.

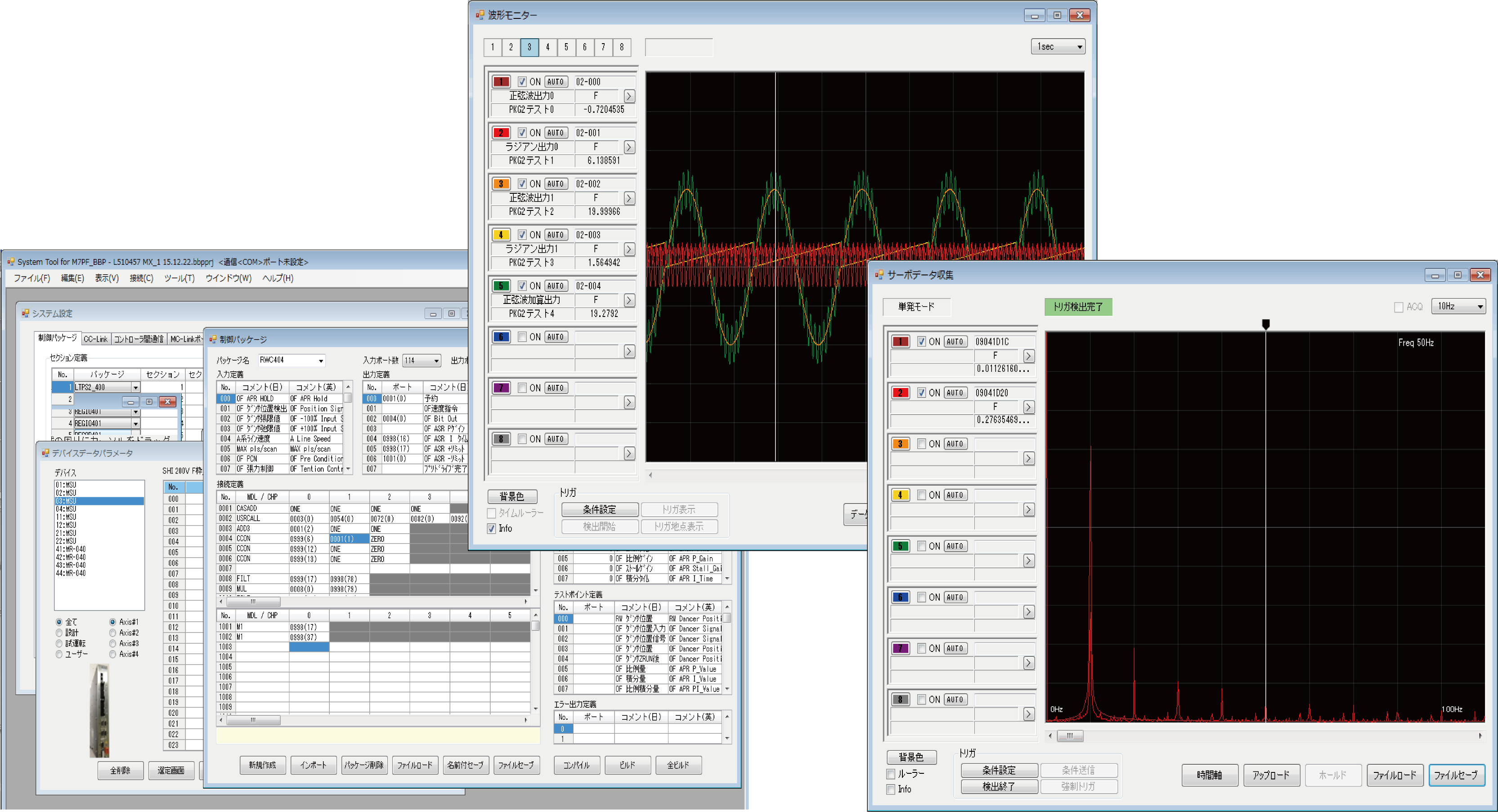

- We have a wide range of unique adjustment tools for controllers. Multi-axis high-speed monitor and FFT analysis functions make it easy to perform periodic analysis of tension fluctuations and mechanical vibrations.

- By connecting the computer containing the adjustment tool to the Internet via a Wi-Fi router, you can perform remote monitoring and fault diagnosis.

PRODUCTS

Drive control system for Roll-to-Roll transport equipment System MXⅡ

Roll-to-roll conveyance control system

Our company develops and sells unique controllers, drivers, motors, etc. necessary for Roll-to-Roll conveyance control. We customize the software to suit our customers and achieve high-precision conveyance.

Features

Specification

The following parts will be assembled into the control panel before delivery.

- Control controller (control software)

- Vector motor, servo motor

- Motor drive driver

- I/O unit

- PG cable and other cables

Our engineers will perform parameter adjustments at the customer's factory to achieve the customer's desired accuracy.

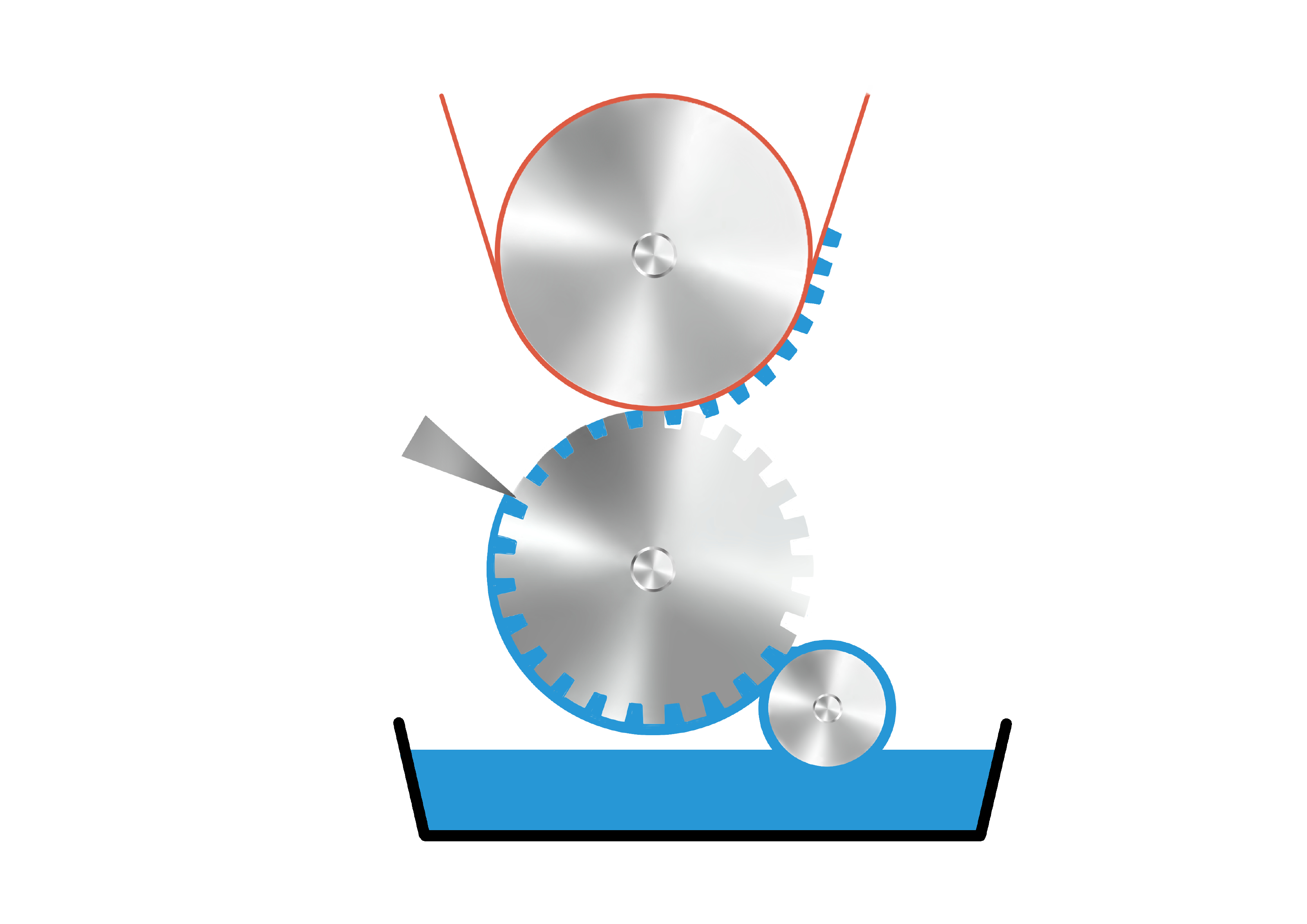

■Gravure printing machine

- Reducing printing and paper splicing loss

- Flexible selection of color units

- Supports back printing and reprinting

- Coater mode

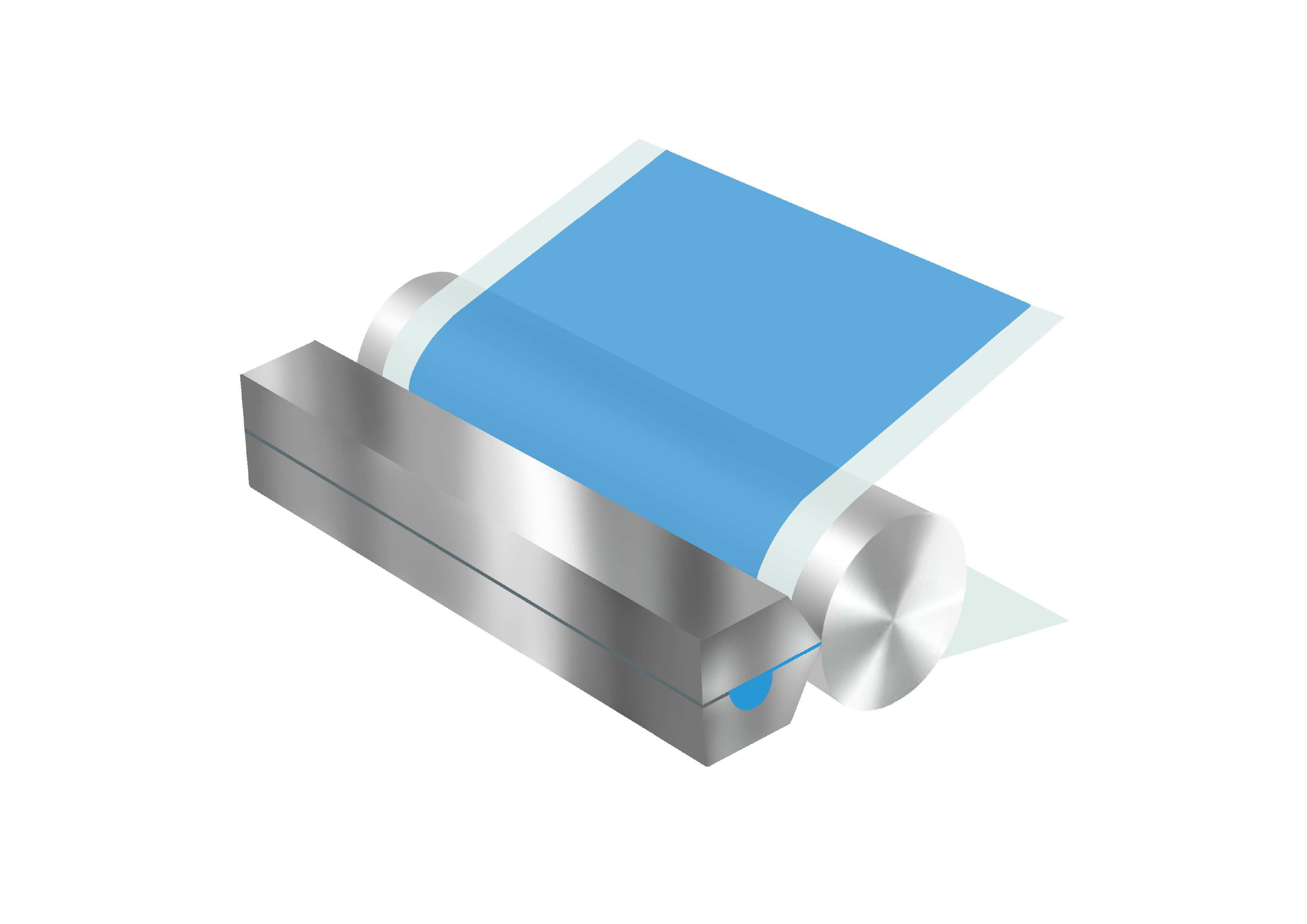

■Coater

- Compatible with intermittent coating

- Realization of low speed and low ripple conveyance

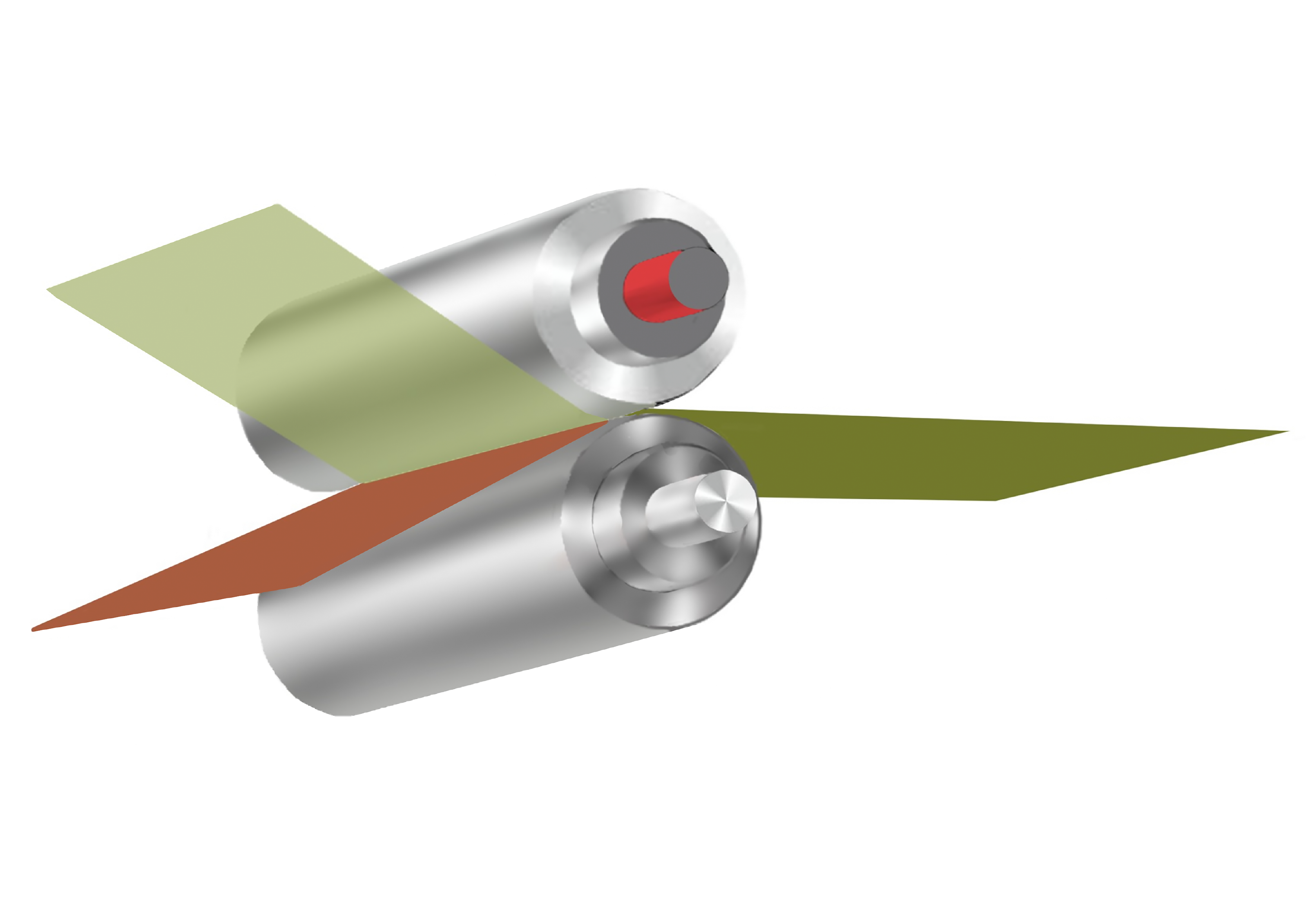

■Laminator

- Suppression of winding wrinkles and winding misalignment through tension control, and suppression of wrinkles after processing

- Compatible with various lamination methods

- Interlocking with auxiliary equipment (other than main drive) control