*1 If the welding interval time is short, calculation data cannot be accumulated.

*2 Dustproof rack is optional.

PRODUCTS

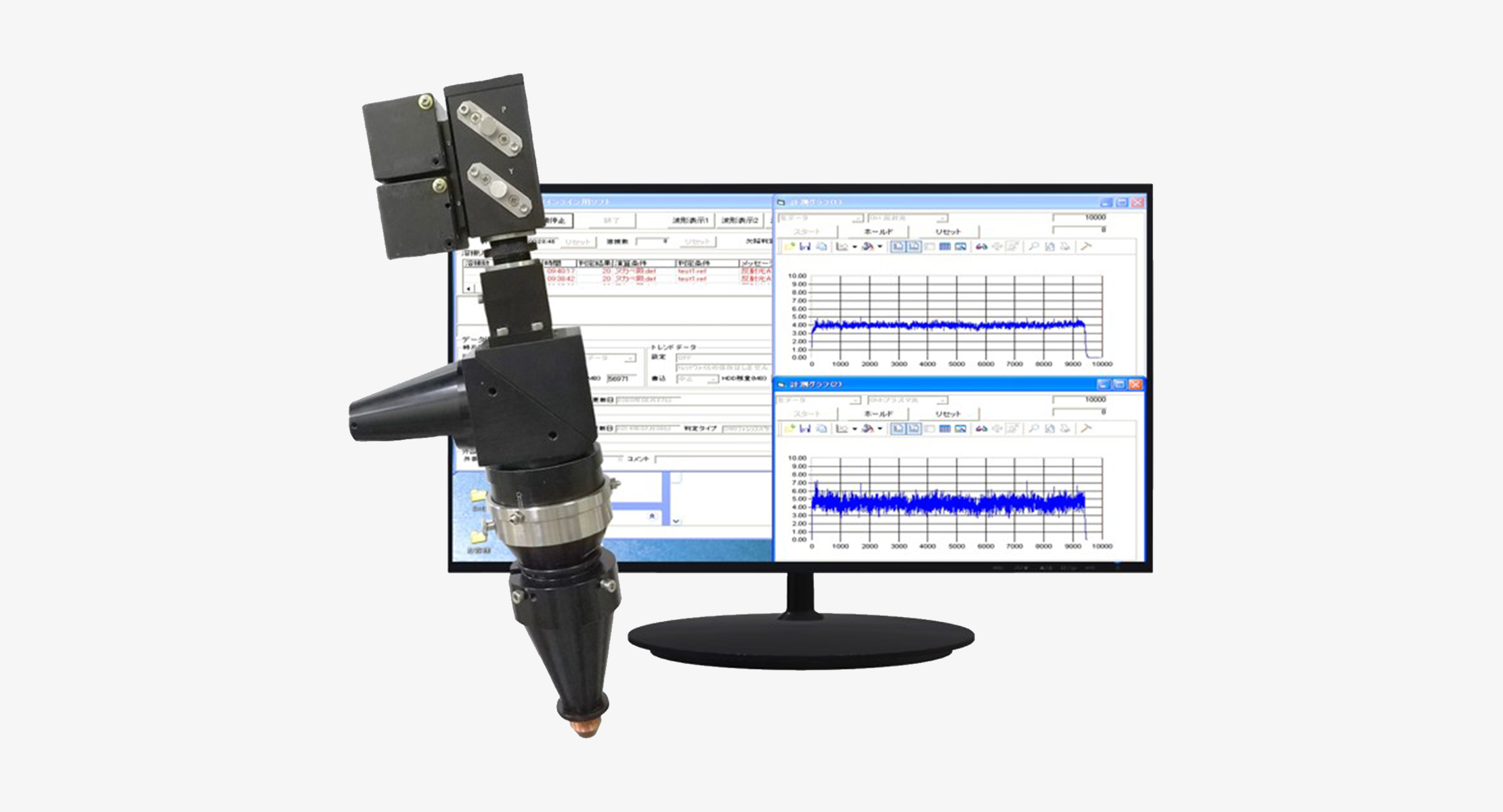

Welding monitoring system Z’eye

Process tools

Expert in laser welding quality control!

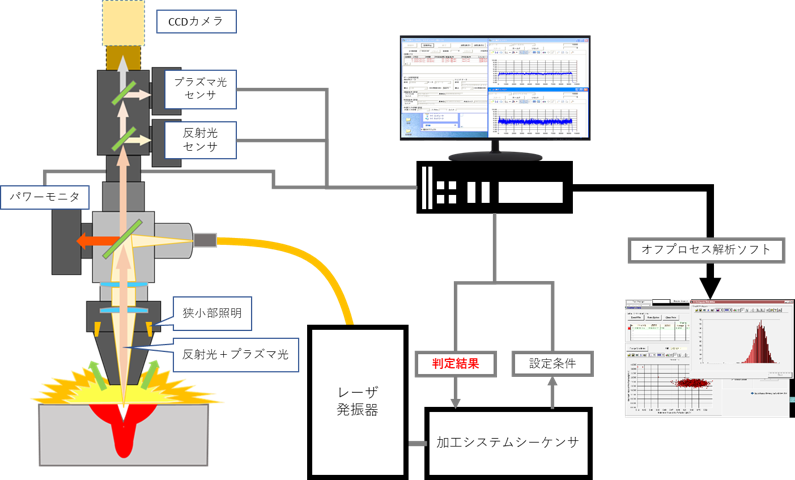

The plasma light and reflected light during laser welding are monitored in-line to monitor the welding status in real time.

The plasma light and reflected light during laser welding are monitored in-line to monitor the welding status in real time.

Features

- Monitor welding status inline

- Can be attached to laser oscillators from various manufacturers

- Compact design with laser coaxial monitoring

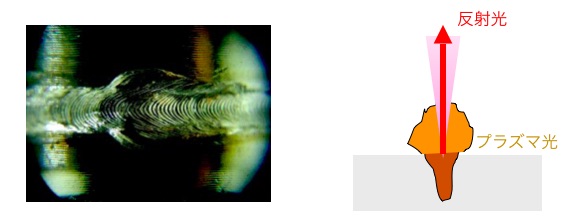

Principle

- Monitoring plasma light and reflected light generated during laser welding on the same axis of the laser beam

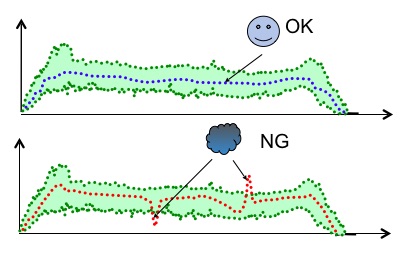

- Create a reference from the data of non-defective products and set the area

- Determined as a defect when a signal exceeding the reference area is detected

Specification

| Item | Specifications | Remarks |

|---|---|---|

| 1. Target laser maximum average output | 5kW or less | |

| 2. Number of input channels | Max. 6ch (8ch option) | |

| 3. Sampling frequency (resolution) | 0.5 - 50kHz | |

| 4. Maximum welding time: | 512 seconds or less | 1 channel input, 0.5Hz sampling |

| 5. Minimum welding interval time | 0.5sec | *1 |

| 6. Sensor measurement wavelength | ||

| 1) Reflected light | YAG: 1,064nm, FL: 1,070nm | |

| 2) Plasma light | 300 - 1000nm | |

| 7. External dimensions | ||

| 1) Signal processing device | 650D x 450W x 1530Hmm | When using dustproof rack *2 |

| 2) Sensor head | 95×52×150L CCD, output | Housing not included |

| 8. Weight | ||

| 1) Signal processing equipment and dustproof rack *2 | Approximately 80 kg | Including computer and dustproof rack *2 |

| 2) Sensor head | Approx. 0.9kg | |