PRODUCTS

SWA “UV” Laser series

Laser annealing equipment

Laser annealing equipment for next generation power devices

Application example) SiC ohmic contact generation, activation, etc.

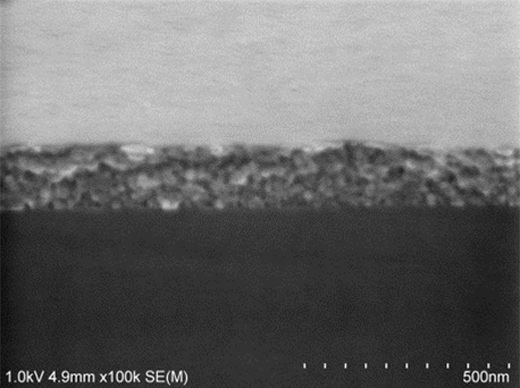

The metal-SiC interface is heated to a high temperature while suppressing the temperature rise of the non-irradiated surface, and ohmic contact is created using OPTSWING* (a unique high-speed scanning method).

Application example) SiC ohmic contact generation, activation, etc.

The metal-SiC interface is heated to a high temperature while suppressing the temperature rise of the non-irradiated surface, and ohmic contact is created using OPTSWING* (a unique high-speed scanning method).

Features

High-speed scanning using OPTSWING

Achieves high throughput by scanning the beam.

Compatible with 8 inch wafers

Capable of processing wafers from small pieces to 8 inches.

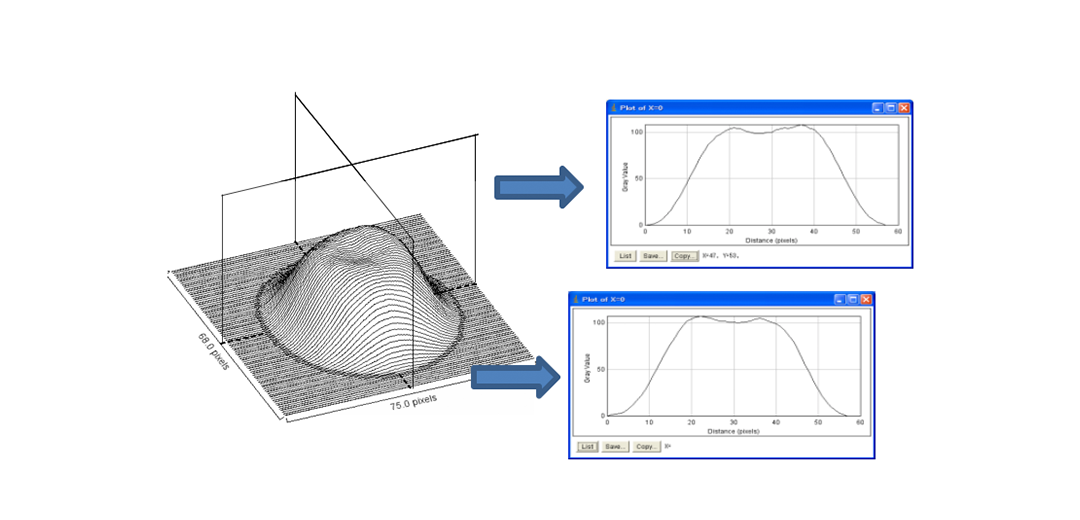

Top hat beam

Ensures excellent in-plane uniformity.

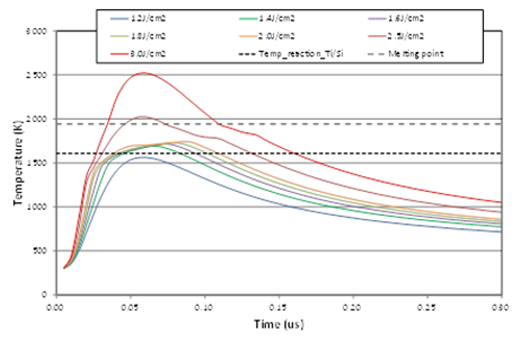

Simulation technology

Optimization of annealing conditions is possible through temperature simulation.

Process atmosphere control Various monitoring functions (beam shape, etc.)

Specification

| Model | SWA-20US | |

|---|---|---|

| Wafer Size | 〜φ200mm (8in) | ◯ |

| Laser | UV-YAG Laser | 10W |

| Beam Size | FWHM | φ100um |

| Process Atmosphere | N2 / Air | |

| Process Temperature | Room Temperature | |

| Wafer Handing | Automatic | |